Pipe fittings can be used in Petrochemical industry;aviation and aerospace industry; pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc.

Determine specifications and materials: Firstly, determine the specifications and materials of the elbow according to the engineering needs. This includes the diameter, wall thickness, and whether special materials (such as stainless steel, alloy steel, etc.) are required for the elbow.

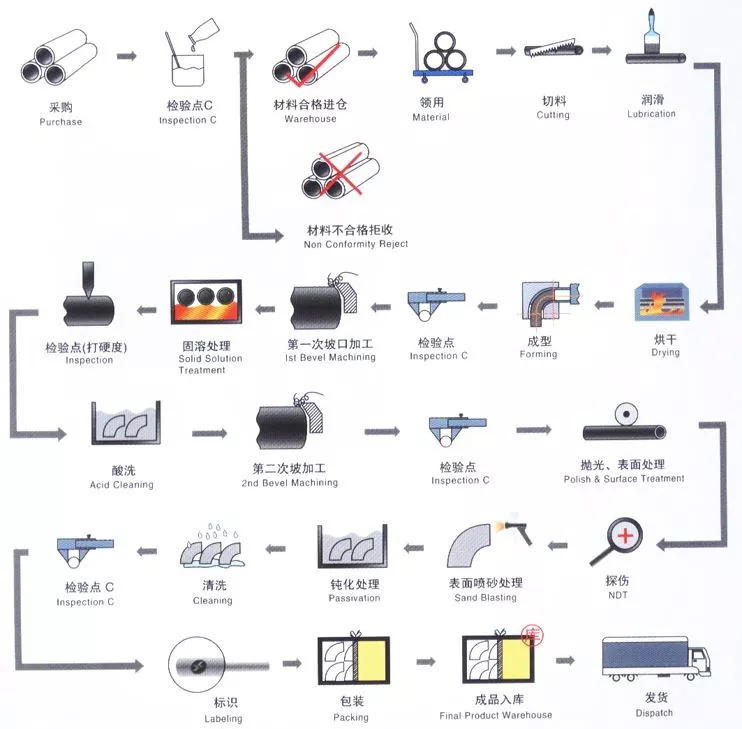

Cutting and pre-treatment: Select the appropriate pipe blank for cutting according to the size requirements of the elbow. After cutting, the pipe blank needs to be pre treated, such as removing surface oxides, coating lubricants, etc., to ensure smooth processing in the future.

Hot push molding: Hot push molding is the most common process in seamless elbow production. It uses a dedicated elbow pushing machine, core mold, and heating device to move the billet placed on the mold forward under the push of the pushing machine, and is heated, expanded, and bent into shape during the movement. The deformation characteristics of a hot push elbow are determined based on the law that the volume of the metal material remains unchanged before and after plastic deformation. The diameter of the pipe blank used is smaller than the diameter of the elbow, and the deformation process of the blank is controlled by a core mold, so that the compressed metal at the inner arc flows and compensates for the thinning of other parts due to diameter expansion, thereby obtaining an elbow 410 with uniform wall thickness.

Finishing and inspection: The elbow formed by hot pressing needs to undergo finishing processes, including shot blasting to remove the oxide scale on the inner and outer surfaces, as well as groove treatment for welding. In addition, it is necessary to inspect the elbows, including size checks, non-destructive testing, etc., to ensure that the product quality meets the requirements.

Other molding processes: In addition to hot pressing molding, there are also molding processes such as stamping and extrusion. Stamping forming is suitable for small-scale production of high-pressure thick walled stamped elbows, while extrusion forming is suitable for manufacturing large national standard elbows.

Welding and heat treatment: For certain materials of elbows, such as stainless steel elbows, welding and heat treatment may be required. Welding is used to connect elbows and other fittings, while heat treatment is used to improve the mechanical properties of materials.

Anti corrosion treatment: Finally, depending on the usage environment, elbows may require anti-corrosion treatment. This can be achieved by coating anti-corrosion coatings, galvanizing, and other methods to improve the corrosion resistance of the elbow

| Angles | 30° 45° 60° 90° 180° | |||

| Sizes | From 1/2'' to 72'' | |||

| Thickness | SCH20, SCH30, SCH40, STD, SCH80, SCH100. SCH120, SCH160. XXS | |||

| Standard |

|

|||

| Surface |

|

|||

| Usage | Petroleum,chemical ,electric power , metallurgy , shipbuilding, construction etc. | |||

| Package | Seaworthy package . Wooden or plywood case or pallet , or as customers' request | |||

| Sample | available | |||

| Remark | Special design is available as customers' requirement |

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth

3. Without lamination and cracks

4. Without any weld repairs

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients

Inspection

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE

7. ASTM A262 practice E

Excellente solution mondiale de pipeline à guichet unique

Excellente solution mondiale de pipeline à guichet unique