Petroleum and Gas Industries pipe flange

- Product Overview

Provide a concise and clear introduction to the product. Mention the type of flange, materials used, and its primary specifications.

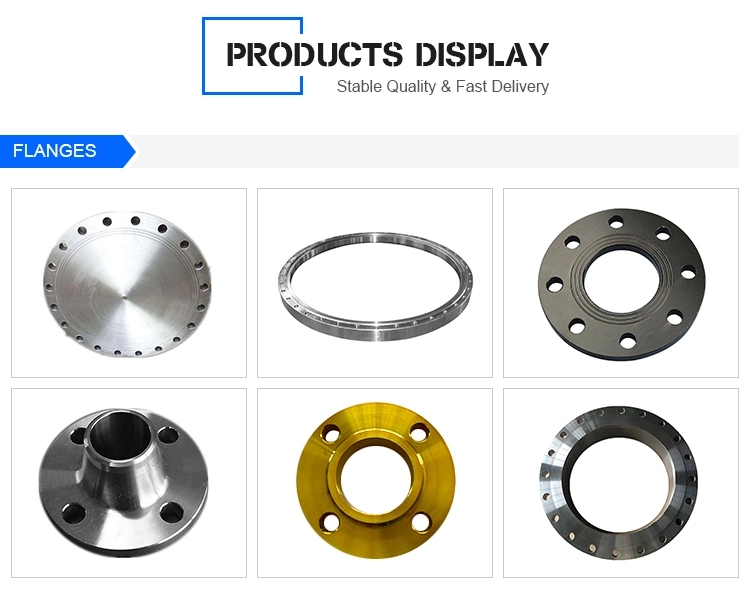

The Carbon Steel Weld Neck Flange is manufactured according to the ANSI B16.5 standard, designed for high-pressure applications and known for its robust construction and ease of installation. Available in a variety of materials, including stainless steel, carbon steel, and alloy steel, this flange type is ideal for connecting pipes, valves, and pumps.

Material: Carbon Steel, Stainless Steel, Alloy Steel

Standard: ANSI B16.5 / B16.47, EN1092-1, ASME

Pressure Rating: Class 150 – 2500

Size Range: 1/2” to 48”

Surface Finish: Anti-rust oil, black painting, or custom coating options available - Application Scenarios

Describe the specific industries and use cases where the product can be utilized.

Example:

The Weld Neck Flange is widely used in:

Petroleum and Gas Industries: Ideal for high-pressure and high-temperature pipeline connections.

Chemical Processing Plants: Suitable for corrosive environments where chemical resistance is required.

Power Generation: Used in power plants for steam and high-temperature water pipelines.

Marine & Offshore Applications: Resistant to harsh marine environments. - Product Features & Advantages

Highlight key features and unique selling points that differentiate your product from competitors.

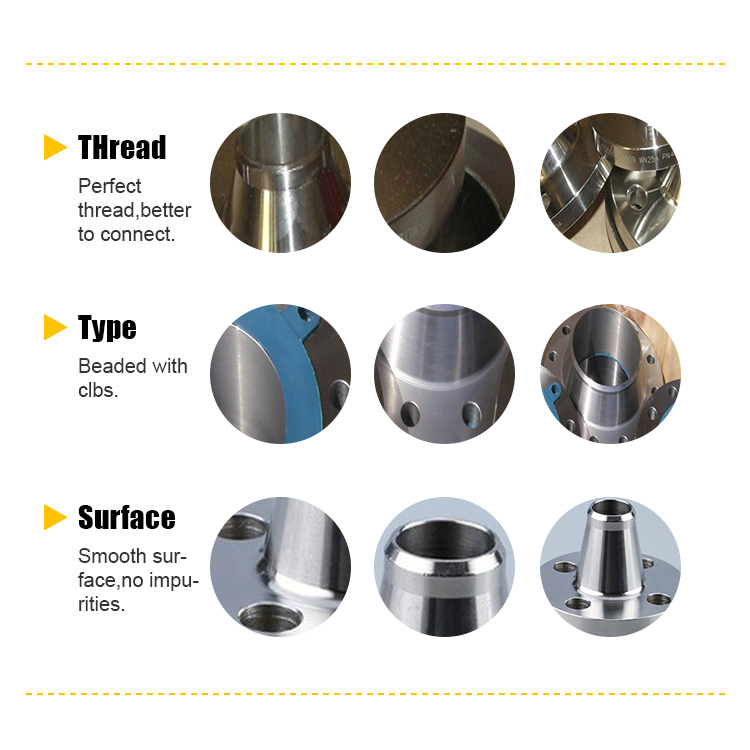

High Strength: Manufactured from premium-grade carbon steel, ensuring durability and high tensile strength.

Corrosion Resistance: With advanced surface treatments such as galvanization or painting, the flange withstands harsh environments.

Precise Dimensions: Ensures tight sealing and perfect alignment with connected pipelines.

Versatile Connection: Compatible with a wide range of pipe types and sizes.

- Quality Assurance & Control

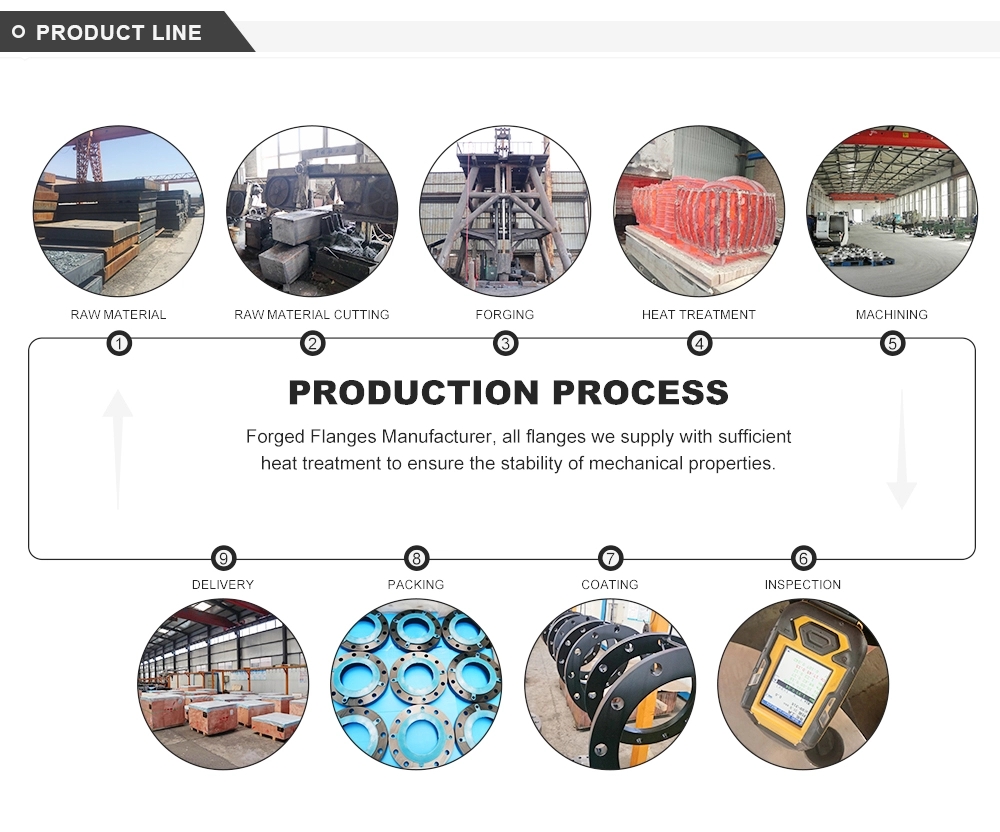

Outline the steps taken to ensure the quality of the product during manufacturing.Heat Treatment ,NON - Our Service:

- 1. Well trained sales team service for you.

- 2. Small MOQ, usually sample is available.

- 3. Support OEM & ODM: we can print logo or customs package according to our client’s requirement.

- 4. Top quality: we have professional QC team to control the quality.

- 5. Timely delivery: we can send goods within 10~40 days after payment, it depend on products and quantity.

- 6. We work with DHL, UPS, FedEx, TNT and EMS for small order. For large order we can arrange shipment by air or by sea.

- 7 Satisfactory service: we treat clients as friends and 24 hours customer service.

ANSI B16.5 600lb ASTM A105N LWN Long Weld Neck Flange Ring Type Joint used for shipbuilding